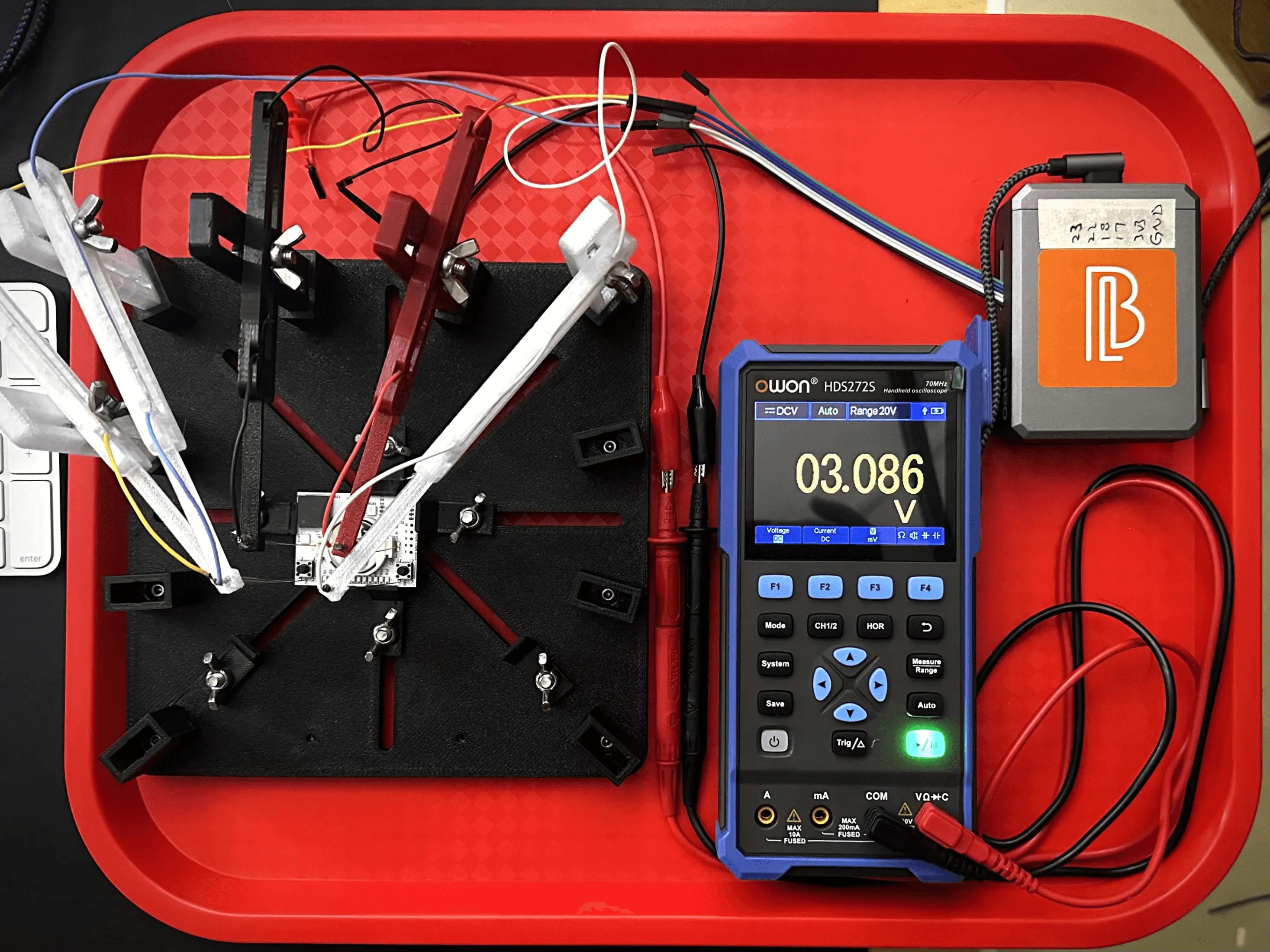

The hardware setup includes a 3D-printed PCB probe jig and an OWON HDS272S multimeter to measure voltage. The Raspberry Pi 4 runs Python scripts that interface with the OWON via its Python API and trigger simulated button presses through GPIO, automating the testing process.

Sensor readings and battery performance data are sent to Adafruit IO, allowing for real-time monitoring and visualization on a cloud dashboard. This enables the collection of long-term data and trends without manual intervention.

This project demonstrates the integration of hardware, software, and cloud systems to streamline testing workflows. It is a practical application for makers and engineers who need consistent, repeatable battery testing while gaining experience with automation, data logging, and IoT connectivity.

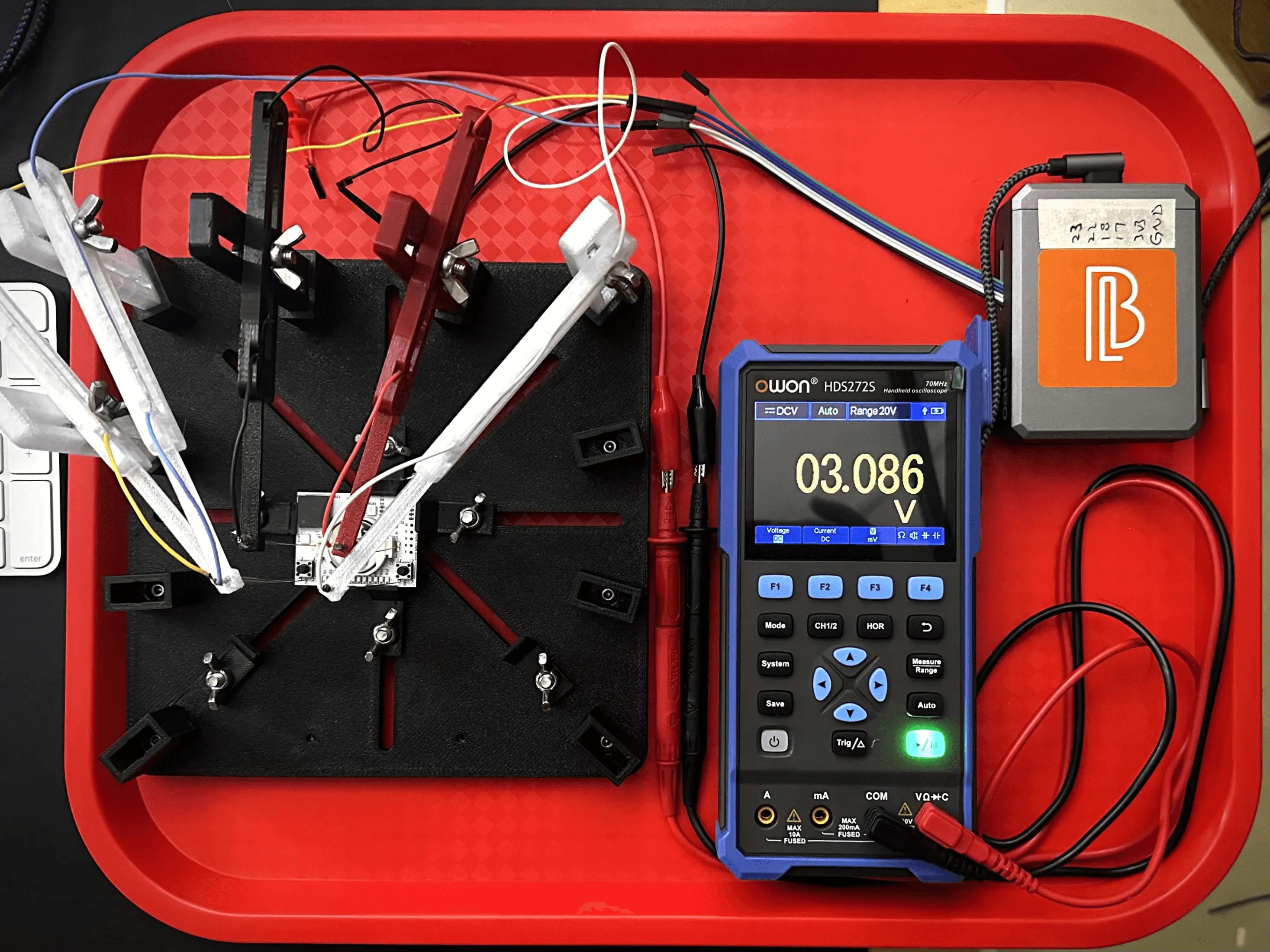

The hardware setup includes a 3D-printed PCB probe jig and an OWON HDS272S multimeter to measure voltage. The Raspberry Pi 4 runs Python scripts that interface with the OWON via its Python API and trigger simulated button presses through GPIO, automating the testing process.

Sensor readings and battery performance data are sent to Adafruit IO, allowing for real-time monitoring and visualization on a cloud dashboard. This enables the collection of long-term data and trends without manual intervention.

This project demonstrates the integration of hardware, software, and cloud systems to streamline testing workflows. It is a practical application for makers and engineers who need consistent, repeatable battery testing while gaining experience with automation, data logging, and IoT connectivity.

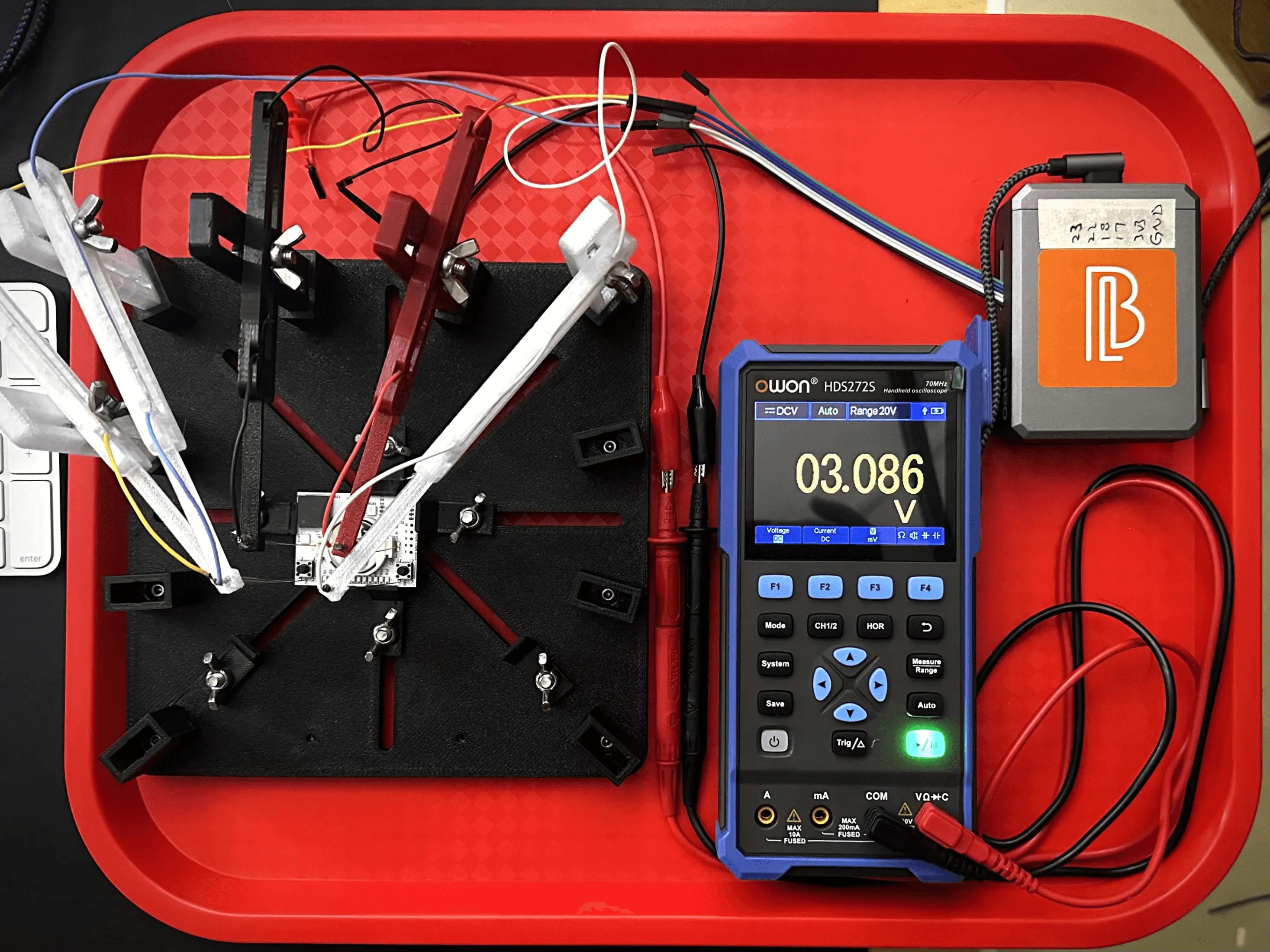

The hardware setup includes a 3D-printed PCB probe jig and an OWON HDS272S multimeter to measure voltage. The Raspberry Pi 4 runs Python scripts that interface with the OWON via its Python API and trigger simulated button presses through GPIO, automating the testing process.

Sensor readings and battery performance data are sent to Adafruit IO, allowing for real-time monitoring and visualization on a cloud dashboard. This enables the collection of long-term data and trends without manual intervention.

This project demonstrates the integration of hardware, software, and cloud systems to streamline testing workflows. It is a practical application for makers and engineers who need consistent, repeatable battery testing while gaining experience with automation, data logging, and IoT connectivity.